Cracks in buildings are common yet concerning issues that homeowners, builders, and property investors frequently encounter. While minor cracks might seem harmless, ignoring them can lead to significant structural damage, expensive repairs, and potential safety hazards.

The consequences of ignoring building cracks are not only financial but also pose serious safety hazards. Unresolved cracks can lead to expensive repairs, decreased property value, and potentially hazardous living or working conditions. Therefore, timely detection, evaluation, and repair are essential steps to safeguard your investment.

Understanding the causes of cracks, how to prevent them, and knowing the appropriate repair methods is crucial for maintaining structural integrity and ensuring long-term property value.

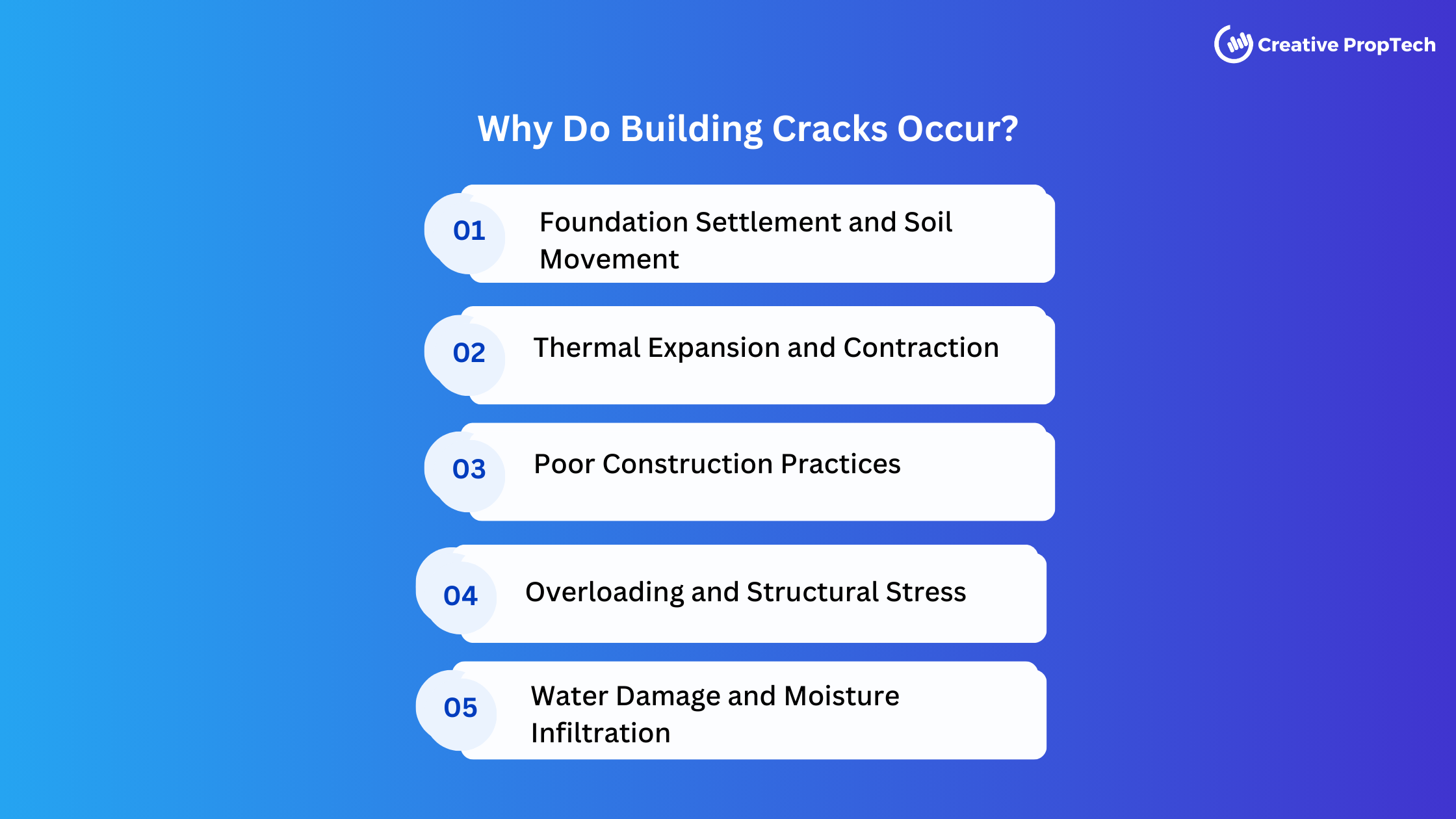

Why Do Building Cracks Occur?

Building cracks typically result from a variety of factors, ranging from natural causes to construction defects. Understanding these factors is essential in effectively diagnosing and resolving crack-related issues

1. Foundation Settlement and Soil Movement

One of the most common reasons for cracks is foundation settlement. As buildings age, the foundation settles into the soil beneath, causing minor shifts and movements. Unequal settlement, often due to uneven soil moisture, expansive clay, or poorly compacted fill, results in stress points and cracks in walls, floors, and ceilings.

In regions with high clay content, soils expand significantly when wet and shrink when dry. This cycle of expansion and contraction puts continuous pressure on foundations, eventually leading to cracks.

2. Thermal Expansion and Contraction

Building materials naturally expand in heat and contract in cooler temperatures. Constant exposure to temperature variations causes stress on structural elements. If not accommodated through expansion joints or proper design, these repeated movements result in visible cracks over time.

3. Poor Construction Practices

Poor workmanship, incorrect material mixing ratios, or inadequate curing of concrete can contribute significantly to structural cracks. For example, using substandard concrete mixes or improperly mixed mortar reduces material strength, increasing the likelihood of cracks forming shortly after construction.

4. Overloading and Structural Stress

Buildings are designed to withstand certain loads. When they are subjected to excessive weight, whether from additional floors, heavy furnishings, or modifications without structural assessment, the resulting overload stresses beams, columns, and foundations, causing structural cracks.

5. Water Damage and Moisture Infiltration

Moisture penetration from leaks or inadequate waterproofing leads to the weakening of structural components. Water infiltration corrodes steel reinforcements within concrete, causing rust expansion and internal stresses, leading to cracking and concrete spalling.

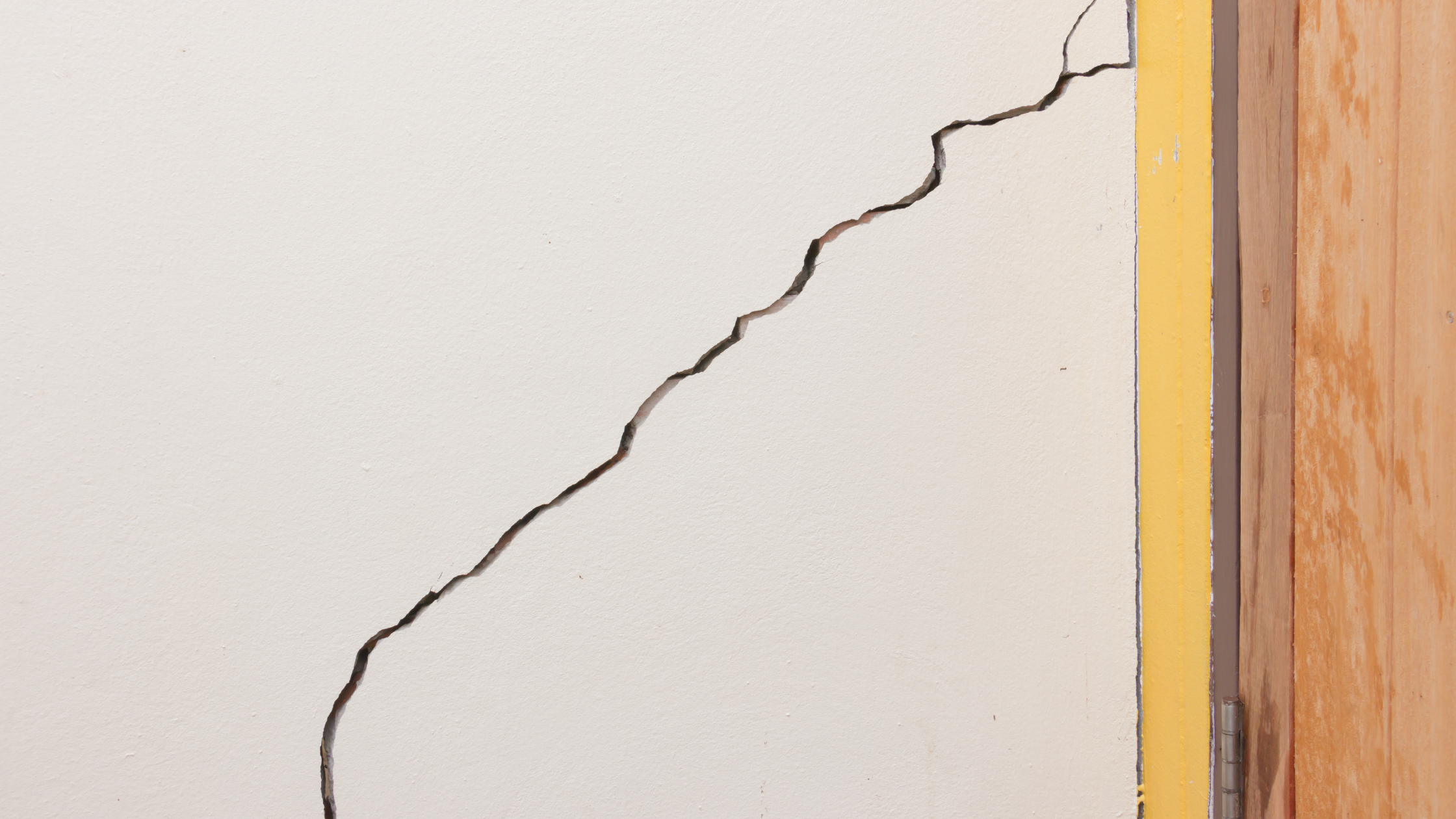

Types of Cracks in Buildings

Identifying the type of crack is essential for determining its severity and the necessary intervention.

- Hairline Cracks: Usually minor and superficial, commonly found in plaster or paint layers due to normal building settling or thermal movements.

- Vertical Cracks: Often indicate normal settlement but can be serious if wide or rapidly expanding. Commonly appear around window and door frames.

- Horizontal Cracks: Typically more serious and can suggest structural issues or significant foundation pressure.

- Diagonal Cracks: Usually indicate uneven foundation settlement or structural stress.

- Step-like Cracks: Common in masonry walls due to foundation movement, poor mortar quality, or structural loading issues.

How to Prevent Building Cracks

Preventive measures are key to reducing the occurrence of building cracks and maintaining the integrity of the structure.

1. Soil Testing and Proper Foundation Design

Conduct thorough soil testing before construction. Understanding the soil type and behavior ensures proper foundation design tailored to soil conditions. Proper compaction and suitable foundation depth significantly reduce risks associated with soil movement.

2. Quality Construction Practices

Employ skilled workers and adhere strictly to construction standards and guidelines. Ensure materials such as concrete and mortar are mixed accurately and adequately cured. Good quality control practices during construction can substantially reduce future cracking.

3. Incorporate Expansion Joints

Buildings should have strategically placed expansion joints, especially in large structures, to accommodate thermal expansion and contraction. This simple step prevents excessive stress buildup within the structure.

4. Adequate Waterproofing

Implement comprehensive waterproofing solutions, especially in areas exposed to water or moisture, such as basements, bathrooms, and rooftops. Regular maintenance and prompt repair of any leaks prevent water-related structural damage.

5. Regular Inspection and Maintenance

Routine checks and preventive maintenance allow for early identification and resolution of minor cracks before they escalate. Scheduled inspections can prevent costly repairs by addressing issues proactively.

Effective Repair Techniques for Building Cracks

Addressing cracks promptly and effectively is crucial to prevent structural deterioration. Here are some recommended repair methods:

1. Sealants and Fillers

For minor hairline or superficial cracks, elastomeric sealants and epoxy fillers are highly effective. These materials accommodate minor movements, provide water resistance, and enhance visual aesthetics.

2. Structural Crack Stitching

This method involves inserting stainless steel rods or bars across the crack and filling them with grout or epoxy resin. Crack stitching effectively reinforces cracked masonry walls, redistributing loads and preventing further crack propagation.

3. Injection Grouting

For deeper and more structural cracks, especially in concrete, injection grouting is effective. Epoxy or polyurethane resins are injected under pressure to fill voids, restoring structural integrity and preventing water infiltration.

4. Reinforcement and Underpinning

Serious foundation-related cracks require underpinning techniques, which strengthen and stabilize foundations. Methods include installing concrete piers, helical piers, or micro piles beneath the existing foundation to support and lift structures.

5. Waterproofing Treatments

Water-induced cracks are repaired and prevented using advanced waterproofing solutions, including crystalline coatings, waterproof membranes, or liquid-applied barriers, enhancing durability and protection from moisture.

FAQs on Building Cracks

Are all cracks in buildings a sign of serious structural problems?

No, not all cracks are severe. Minor hairline cracks are typically harmless, but significant or rapidly expanding cracks may indicate serious structural issues.

Can I repair cracks myself, or should I hire a professional?

Minor superficial cracks can often be repaired by homeowners. However, structural cracks require assessment and repair by professional engineers or qualified specialists.

How often should a building be inspected for cracks?

Ideally, buildings should undergo professional inspections at least once every 1-2 years to detect potential problems early.

What is the average cost of repairing structural cracks?

The repair cost varies significantly depending on severity, but structural repairs can range from ₹50,000 to several lakhs for extensive issues.

Can waterproofing help prevent cracks in buildings?

Yes, effective waterproofing prevents moisture-related structural damage, significantly reducing the likelihood of cracks caused by water infiltration.

What are the first signs of structural cracking I should look out for?

Early signs include wide or rapidly expanding cracks, diagonal or step-like patterns, sticking doors/windows, or visible sagging in floors and ceilings.

Is soil testing necessary for every construction project?

Yes, soil testing is highly recommended for every project to ensure the proper foundation design and prevent foundation-related cracking.

How long do crack repairs typically last?

Properly executed repairs using quality materials can last for many years, especially when combined with regular maintenance and inspections.